Maximizing the Lifespan of Your Equipment with Regular Packaging Machine Repair

Maximizing the Lifespan of Your Equipment with Regular Packaging Machine Repair

Blog Article

How to Take Full Advantage Of Efficiency With Specialist Packaging Machine Fixing Provider

Understanding the essential role of packaging equipments, services must acknowledge the indicators that suggest a demand for repair work and the benefits of engaging professional solutions. Selecting the ideal repair service and applying effective preventative upkeep strategies stays important.

Understanding Product Packaging Machine Significance

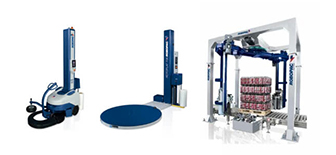

Why is the product packaging device took into consideration an important component in modern production? Product packaging machines play an important duty in enhancing functional performance, item preservation, and consumer allure. In an open market, the capability to plan items rapidly and effectively straight influences a firm's profits. High-speed packaging devices can enhance manufacturing procedures, reducing labor costs and reducing human error, while preserving high throughput prices.

Moreover, advanced product packaging makers are developed to accommodate various product packaging types, such as bottles, bags, and boxes. This versatility permits suppliers to adjust to altering market demands and customer choices without considerable downtime. Additionally, effective product packaging makes sure product honesty throughout transport and storage space, decreasing waste and wasting and inevitably adding to sustainability efforts.

Moreover, packaging machines incorporate effortlessly with other making systems, facilitating a smooth operations from production to circulation. This interconnectedness not only improves productivity however also supplies important information analytics for constant renovation. In summary, the value of product packaging makers in modern-day manufacturing can not be overemphasized; they are important for keeping competitive advantage and accomplishing functional excellence in today's hectic organization environment.

Indications Your Equipment Needs Repair

Determining the indicators that your product packaging device needs fixing is essential for preserving manufacturing effectiveness and decreasing downtime. Regular tracking of equipment efficiency can help spot problems prior to they rise right into significant problems.

One of the very first indications is an unusual increase in noise levels throughout procedure. It might show mechanical wear or imbalance if the machine starts to produce grinding or clattering audios. Furthermore, irregular product result, such as irregular product packaging or mislabeling, can recommend that the equipment's calibration is off, needing immediate attention.

Another important indicator is constant mistake messages or unforeseen closures. These disruptions can severely influence result and signal underlying electric or software concerns. In addition, if you see a decrease in rate or effectiveness, with the maker taking longer to complete jobs, it may be a precursor to more severe mechanical failings.

Lastly, physical indicators such as fraying belts, dripping fluids, or too much vibration needs to not be overlooked, as they usually indicate elements that are on the edge of failure - packaging machine repair. Without delay resolving these signs can prevent pricey repair services and guarantee optimum functional performance

Advantages of Expert Repair Service Solutions

Furthermore, professional repair solutions usually have accessibility to sophisticated diagnostic tools and modern technologies that promote a my latest blog post thorough analysis of devices condition. This not just aids in immediate fixings however likewise enables anticipating maintenance, preventing future breakdowns and expanding the life expectancy of machinery.

In addition, using expert services can cause improved safety and security requirements, as qualified specialists are fluent in market regulations and finest practices. This lowers the danger of accidents triggered by improper handling or upkeep. Ultimately, the financial investment in professional fixing solutions translates to set you back financial savings by enhancing machine efficiency, enhancing product top quality, and making sure compliance with safety and security standards, all of which add to a more effective production atmosphere.

Picking the Right Repair Work Solution

Additionally, assess their feedback time and accessibility. A repair service that offers 24/7 assistance can stop small problems from intensifying right into pricey manufacturing stops. Try to find business that offer a detailed solution contract, detailing their guarantees, pricing frameworks, and parts availability. This openness guarantees that you site link are not confronted with unforeseen prices or delays.

Moreover, check client testimonials and endorsements to evaluate the dependability and professionalism and reliability of the company. A trusted business will certainly have a history of pleased customers, which speaks volumes regarding their solution top quality. Make certain that the technicians are certified and trained in the newest innovations and ideal techniques, as this expertise is important for efficient repair services and upkeep. By meticulously picking a repair solution, you can boost the long life and efficiency of your product packaging equipments.

Preventative Maintenance Techniques

Implementing preventative upkeep approaches is necessary for making sure the ideal performance and long life of product packaging makers. Frequently scheduled upkeep not only lowers the probability of unforeseen failures yet likewise enhances total operational performance.

A positive maintenance timetable need to include regular assessments, lubrication of moving components, and looking for wear and tear on crucial parts. These assessments can identify possible issues prior to they escalate right into costly repair services or downtime. Keeping accurate documents of upkeep activities can aid track device efficiency trends and guide future upkeep decisions.

Training employees on proper operating treatments is another essential aspect. Workers should be enlightened on acknowledging early indications of equipment malfunction, which can promote timely intervention. In addition, employing vibration evaluation and thermal imaging technology can even more improve the upkeep strategy by pinpointing issues that may not be visible to the nude eye.

Verdict

To conclude, making best use of performance with skilled packaging machine fixing services necessitates a positive approach that consists of routine maintenance, prompt repairs, and the proficiency of competent specialists. Implementing innovative diagnostic devices and promoting relationships with dependable repair work solutions add to enhanced functional performance and lowered downtime. By prioritizing these approaches, services can guarantee the long life and effectiveness of their product packaging machinery, eventually causing improved efficiency and adaptability in action to evolving production needs.

Understanding the important role of product packaging machines, organizations must identify the signs that show a need for fixing and the benefits of engaging specialist services.Addressing the indications of wear and malfunction in product packaging machines immediately is only part of the formula; leveraging expert repair solutions can dramatically improve operational efficiency.Choosing the appropriate packaging helpful hints maker fixing service is crucial for keeping operational performance and lessening downtime. By very carefully choosing a fixing solution, you can boost the long life and efficiency of your product packaging machines.

In conclusion, maximizing efficiency with experienced product packaging machine repair services demands an aggressive strategy that consists of normal maintenance, prompt repairs, and the competence of competent technicians.

Report this page